MakerStudio at UA Offers Free 3D Printing for Students

November 28, 2018

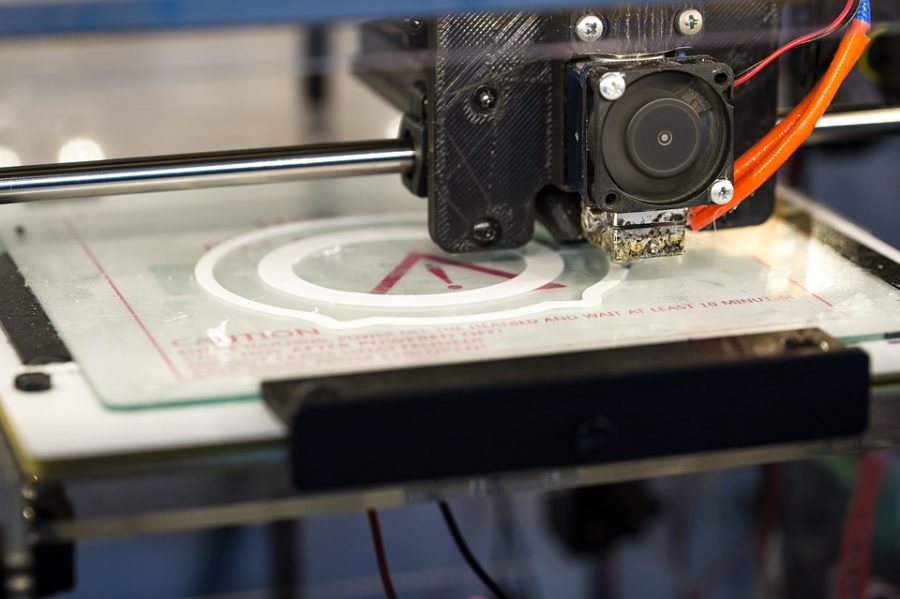

The University of Akron offers free 3D printing for students through MakerStudio, found on the ground floor of Bierce Library.

Made by the MakerStudio 3D printers, the left wand is designed based off a Pottermore wand and the right wand is designed based on the one that belongs to Harry Potter character, Voldemort.

Students are limited to 10 personal prints or 30 print hours, the University Libraries website said. However, students have access to unlimited academic prints, which include assignments and projects for classes.

In order for a student’s design to be compatible for the 3D printer, the MakerBot fifth Generation, file formats must be exported in .stl, .obj or .thing, the website said. The object also must fit within the 9.9 x 7.8 x 5.9-inch build platform of the 3D printer.

Maria Hawkins, the coordinator of applied technology research and learning services at University Libraries said in the past students have made a functional guitar, a functional clock and full skeletons of dinosaurs using the 3D printer.

The 3D printer uses 1.74 mm Polylactic Acid filament, the website said.

The benefits of using PLA filament as opposed to other thermoplastics, Hawkins said, is that it is the most common filament on the market and it allows for many different colors, giving students more freedom in their designs.

PLA filament also is user-friendly, causing less failed models and wasted time, Hawkins said.

Students can design their models using computer-aided design programs such as AUTOCAD or SketchUp. If students prefer not to design their objects, they can use premade designs from free design repositories. A list of programs and websites can be found on the University Libraries website.

The time it takes for a printing to complete depends on the size and infill of the object, the website said. The infill of the object is the repetitive pattern in the inside of the design that gives the object structural strength and weight.

Hawkins said that the 3D printer runs nearly 24/7 during the week. Last semester, MakerStudio received 800 print submissions, many being more than one piece, she said.

If students are creating a print for a class, they must submit the design three to five business days before the due date and provide the course name and instructor.

If students run out of non-academic prints, they will not be provided with any other prints. However, each semester, the student’s print time is reset to zero, Hawkins said.